SMART HAMMER SYSTEMS

THE SMART HAMMER

US Patent # 5,686,652, is a complete equipment package designed to generate, record and analyze impact acoustic signatures. Think of it as quantified tap testing or hammer sounding; time-proven, cost-effective methods for inspecting large composites for voids and damage. Impact generators are both adjustable and very repeatable. Powerful software that's easy to use records and quantifies the acoustic signatures the SMART HAMMER impact generator produces, making long-term acoustic signature comparisons and defect characterizations repeatable and non-subjective.

SUITCASE MODEL carries air logic and a number of impact generators, vacuum generator , high efficiency filtration and a special muffler. Air consumption approximately 4.5 CFM @ 2 Hz impacter frequency with high impact model. Hoses are 5 meters long. Controls for tapping rate, impact force, limpet vacuum and soft-stop and soft-start are located on control panel. Suitcase is O ring sealed and splash proof when closed.

"Limpet" style IMPACT GENERATOR BASES are vacuum attached to the test article. Contoured or cast bases available. Solvent resistant, high temperature silicone foam rubber gasket is durable and seals to coarse textured laminate surfaces. Uniform registration against part produces consistent soundings. Low profile impact generator shown attached to base at lower left.

"SLIDER" type impact generators are designed to be hand scanned across test article surfaces for rapid, large area assessments. Base of knurled housing is faced with UHMW polyethylene film for non-marring, low friction travel across painted or gelcoated surfaces. Metal and plastic impact generator strikers available to optimize signature characteristics.

SMART HAMMER ACOUSTIC AMPLIFIERS are rugged & specifically designed for field work. Single and dual channel models with 9 V DC power. 25 Db gain, 20 Hz to 22.5 KHz response. Low noise MOSFET amp & spare chip. 10 turn Gain potentiometer. ON-OFF switch and LED pilot light. MILSPEC BNC connectors. Epoxy potted circuit board. EMI resistant all metal case. Works with all SMART HAMMER SYSTEM acoustic transducers and PCMCIA interface boxes. RG 58 / U cables up to 20 meters powered.

SMART HAMMER SYSTEMS SOFTWARE AND DISPLAYS

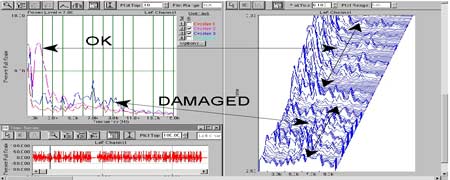

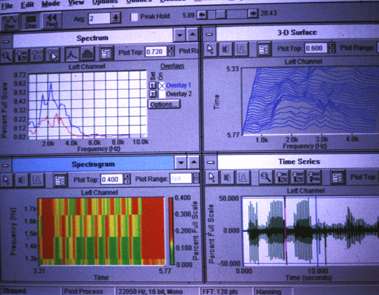

Typical view of SMART HAMMER SYSTEMS software display of impact acoustic signatures, shown in '3-D waterfall' and color spectrum formats. Note how the spectral response changes from intact to damaged areas, and how easy it is to spot. This is what hammer sounding's 'bang-bang-bang-thud-thud-thud' looks like when displayed with spectral analysis software. Each vertical band in the color spectrogram represents one impacter strike, with red indicating the strongest frequencies in the return.

![]()

DEFECT CHARACTERIZATION:

Each series of peaks in the waterfall display, and each colored band in the Color Spectrogram represents one impacter strike. As the impact generator was slid from an intact area to a damaged area, note that the low level frequency responses in the signature dropped out. Spectral peaks were shifted to the right in the 3-D waterfall display, and in the Color Spectrogram below. Higher frequency response increased in the damaged area. Time series display in the lower left shows the relative amplitudes of each impacter strike. Vertical black bar indicates extent of file digitized and displayed.

MINEHUNTER RUDDER SHOCK TRIALS

BP/SP, LLC provided on-site inspection and analysis with SMART HAMMER SYSTEM technology during the shock trials of the all composite minehunter rudder blade prototype. Pre-marked data points were sounded with SMART HAMMER LIMPET type impact generators after each shock event. Soundings were collected from approximately 100 locations. Acoustic signatures from each location were then compared for damage analysis.

SMART HAMMER DISPLAYS 4X

A wide range of display formats are available in the SMART HAMMER SYSTEM acoustic spectral analysis software., Note the 'COLOR SPECTROGRAM' display - with suitable software configurations it will undergo a dramatic color change when a selected acoustic signature is detected, making for easy analysis by minimally trained personnel. Note that the SPECTRUM analysis allows up to 4 acoustic signature characterizations to be presented on the display for use as 'templates,' so that the current soundings can be compared to previous defect or structural acoustic signature types.

Contact BP/SP, LLC to discuss how SMART HAMMER equipment or consulting services fit your nondestructive testing requirements . Recent projects have included:

Fill analysis of containers loaded with high purity sintered nickle alloy for turbine blades

Finding insulation voids in cryogenic fluid storage tanks

Defective core installation in boats and yachts

Detecting plank and fastener deterioration in wooden structures